I got out of the garage around 2AM this morning - I'm going to pay for this later... ZzzZZzzZZZzzzZzzz.

Last night had it's highs and it's lows. I'll start with the good and move to the bad.

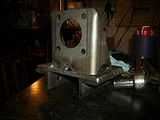

I got stuck at work very late and it took 1:45 to get home from work due to fun traffic. When I got home Dad already had the floor bolted in (the pan we made) and was working on the rear bumper. I don't have any pics from last night - was too busy working to take any. The rear bumper is 3X2 .25 wall and the frame rails were messaged to fit the tubing so it can be bolted through the frame and fulled welded to the ends. We also drilled and mounted the 1" thick by 5" long steel block and put a large piece of angle as a backing plate that will also be welded to the frame. The block will be fully welded as well as bolted - so it should pass tech anywhere we go. I am very confident it will be more then enough - and I overbuild things a bit

While that was going on I was making the last low pressure hoses and did the laborious task of tightening down all of the fittings making sure they stayed pointed in the correct direction. The fuel filter was installed while I was driving home as well - so I installed the battery, changed the oil, filled the system with fluid, pulled the coil wire and manually cycled the ram a few times by moving the tires to try and get as much air out as I could. I hopped into the truck (holy crap this thing got big!) and turned over the motor and cycled the steering left and right to try and get more fluid into the pump without spinning it fast and to try and work out any air before starting.

Here came the moment that has been building for quite some time - Dad popped the coil wire back on the distributer and looked around for things that would either get sucked into the fan or blown away and I got the all clear. Pumped the throttle twice and turned the key and the engine roared to life! Holy crap, that's right - almost forgot I had to cut all of the exhaust off

Well the new fuel pump sure did make the engine run better, maybe the carb won't need rebuilding (what am I kidding, no time - lol) and I tapped the throttle to get it down to low idle and I let it sit while Dad observed the fluid level in the reservoir. Things were looking good, almost ran out of fluid so I shut the motor down - added more fluid and started it back up. Started moving the steering wheel to work the air out and once in awhile I would get this grinding sound and it would feel like the wheel was slipping. It wasn't bad, only did it in one spot so I thought it was just air in the system. Kept working the steering and it got worse, eventually I got no input from the steering wheel at all

Turns out the column adapter is too small for the end of my steering shaft. With the digital dial caliper I got .750 on the steering (I told them I needed 3/4 36 Spline Ford) and the column adapter measures .720. We started scrambling around thinking of ways to make it work, even went out to his 78' to see what we could steal and nothing was going to work without some cutting and welding, not something I want to do on my steering.

I am working with Kelvin @ PSC to get a replacement, after we ran into that problem we continued on and ground the calipers and I made and installed the rear drive shaft. Very few things left to do now...

Here is the deal with the column - shaft measures .75 - column is .72. No amount of toque through a bolt or a vice will close the gap (I've tried)

Just got off the phone - I'll have it in my hands tomorrow.... PSC has

THE best customer support I've ever dealt with.

!