Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New owner from Germany

- Thread starter tody

- Start date

74BroncoCO

Bronco Guru

- Joined

- Nov 3, 2004

- Messages

- 2,374

I would so love to watch the reaction of passersby when you roll down the streets in that rig!!

Congratulations! Now enjoy all that hard work!!

Congratulations! Now enjoy all that hard work!!

Bronco Junkie

So Cal Broncos

- Joined

- Feb 29, 2012

- Messages

- 3,233

Congrats!!!!

another part arrived today, the correct pulley for the power steering pump.

the one that was on there was a "D0AR-A", according to the master parts catalog that's for a 429 engine. bought one marked "AF" on ebay.

here's how they look side by side. couldn't get the new one installed today, as the install tool does not clear the radiator. but i would assume lining the pulleys up should work now:

with the engine sitting back in the engine bay, i had to reroute the winch cables. found a picture of a bronco with that old belleview winch on here, with the cables running around the driver side.

put the controls there:

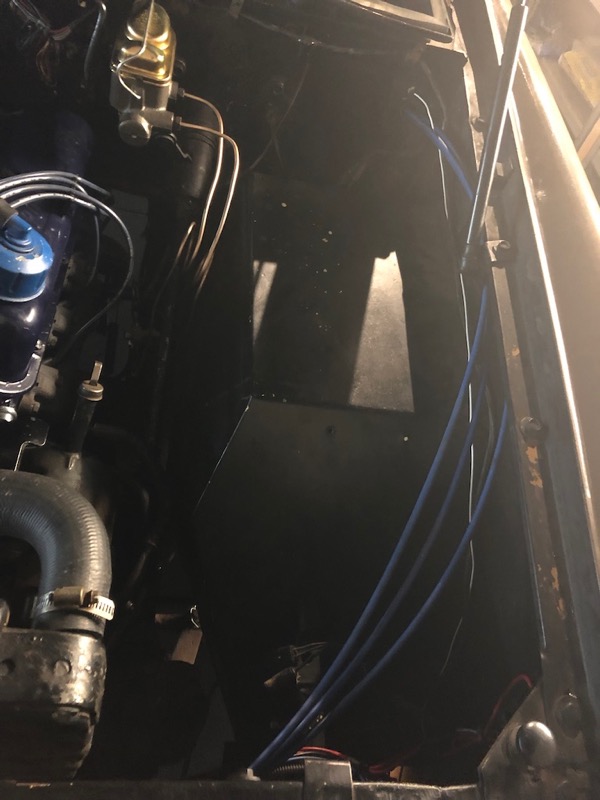

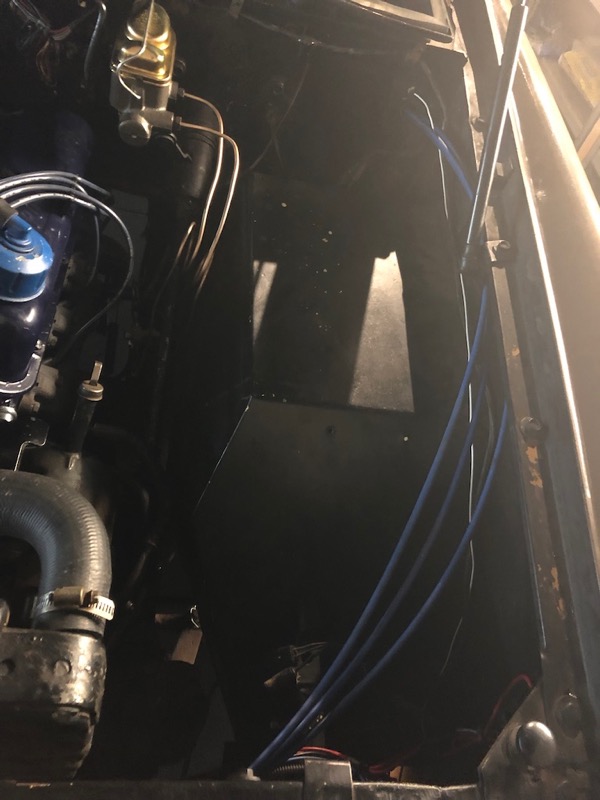

routed them accordingly:

two of them reaching the winch just fine:

but the third one going to the switch came too short:

also, the one going to the brake was rusted and broke when i tried to free it. so i need to source bulk cabling i can crimp onto the old controls. we'll see how that works out!

the one that was on there was a "D0AR-A", according to the master parts catalog that's for a 429 engine. bought one marked "AF" on ebay.

here's how they look side by side. couldn't get the new one installed today, as the install tool does not clear the radiator. but i would assume lining the pulleys up should work now:

with the engine sitting back in the engine bay, i had to reroute the winch cables. found a picture of a bronco with that old belleview winch on here, with the cables running around the driver side.

put the controls there:

routed them accordingly:

two of them reaching the winch just fine:

but the third one going to the switch came too short:

also, the one going to the brake was rusted and broke when i tried to free it. so i need to source bulk cabling i can crimp onto the old controls. we'll see how that works out!

fixed my passenger side door today. it had broken welds here:

which led to cracks right in the middle of the door:

removed the cable housing from one of the winch controls. i must admit, the construction is engineering at it's best. i think i can fix them, will post pictures once i do so.

which led to cracks right in the middle of the door:

removed the cable housing from one of the winch controls. i must admit, the construction is engineering at it's best. i think i can fix them, will post pictures once i do so.

- Joined

- Nov 3, 2003

- Messages

- 47,489

Somewhat common. It's either shoddy workmanship at the factory (not getting it in the jig just right perhaps), or just old age having taken it's toll.

There was supposed to be some cross-caster built in, but I think it's on the order of about half a degree more on the passenger side? I don't remember the details, but I believe that to be close.

So your additional caster would be original, or some impacts in the ensuing 40 years or so. I forget if this is a Dana 30 or a 44, but the 30's were particularly notorious for the axle tubes twisting within the center section. This would skew the caster numbers for sure.

Normally though, the more rigid polyurethane C-bushings will keep some of that in check. But the bushings can only do so much if the tube is twisted in it's socket.

Bottom line though, is that if it drives well down the road without pulling or other strange handling characteristics, I would not worry about the additional half degree or so.

There are others here more versed than I on alignment settings however. Maybe they'll have some advice.

Paul

There was supposed to be some cross-caster built in, but I think it's on the order of about half a degree more on the passenger side? I don't remember the details, but I believe that to be close.

So your additional caster would be original, or some impacts in the ensuing 40 years or so. I forget if this is a Dana 30 or a 44, but the 30's were particularly notorious for the axle tubes twisting within the center section. This would skew the caster numbers for sure.

Normally though, the more rigid polyurethane C-bushings will keep some of that in check. But the bushings can only do so much if the tube is twisted in it's socket.

Bottom line though, is that if it drives well down the road without pulling or other strange handling characteristics, I would not worry about the additional half degree or so.

There are others here more versed than I on alignment settings however. Maybe they'll have some advice.

Paul

- Joined

- Nov 3, 2003

- Messages

- 47,489

Oh, and even though your camber numbers are right in the expected area, you can benefit in the long-term by a little less positive camber. I don't think there have been any set rules on just where the sweet spot is, but I think it's showing to be in the .5 to .75 degree area.

Paul

Paul

- Joined

- Mar 8, 2007

- Messages

- 81,747

LOL it happens bud

put the bronco on my alignment rack today. i'm pretty stumped by the big difference in caster from side to side. any input on that one?

- Joined

- Mar 8, 2007

- Messages

- 81,747

Yeah.. just got to play with it..

Oh, and even though your camber numbers are right in the expected area, you can benefit in the long-term by a little less positive camber. I don't think there have been any set rules on just where the sweet spot is, but I think it's showing to be in the .5 to .75 degree area.

all good advice, thank you.

the axle is a dana 30 - the only chance to change camber is by using shims, correct? next time i order from summitracing, i'll get a set.

concerning camber i'm looking into using 7° bushings. but i will try loosening the track bar bushings and start tightening them on the right side first. that's where the bronco got hit badly, see above. might be that the axle is warped there. maybe i can even it out a little more.

the new radiator did not show up for this weekend, but will be here on monday.

drained the coolant and took out the old today. also swapped the heater control valve for a new shiny chinese part.

with the radiator out of the way, i pressed on the correct power steering pulley. belts now line up perfectly.

still on the list:

- fix the winch control, probably buy a new winch cable

- fix the fuel sending units and wiring

- bleed the brakes (again)

but then it should be roadworthy.

there are a lot more things to fix. the winch bumper is only held on by half the fasteners, for example.

but getting it licensed will be priority no. 1!

the axle is a dana 30 - the only chance to change camber is by using shims, correct? next time i order from summitracing, i'll get a set.

concerning camber i'm looking into using 7° bushings. but i will try loosening the track bar bushings and start tightening them on the right side first. that's where the bronco got hit badly, see above. might be that the axle is warped there. maybe i can even it out a little more.

the new radiator did not show up for this weekend, but will be here on monday.

drained the coolant and took out the old today. also swapped the heater control valve for a new shiny chinese part.

with the radiator out of the way, i pressed on the correct power steering pulley. belts now line up perfectly.

still on the list:

- fix the winch control, probably buy a new winch cable

- fix the fuel sending units and wiring

- bleed the brakes (again)

but then it should be roadworthy.

there are a lot more things to fix. the winch bumper is only held on by half the fasteners, for example.

but getting it licensed will be priority no. 1!

- Joined

- Nov 3, 2003

- Messages

- 47,489

the axle is a dana 30 - the only chance to change camber is by using shims, correct?

I believe so, yes. At one point some companies made king-pin bearing eccentrics, but not sure I ever saw them for the smaller 30. I have some on my 60, but not sure those are even available anymore.

So a spindle shim is likely your only recourse.

However, that's not a bad thing, as they're a very good way to change the angle.

concerning camber i'm looking into using 7° bushings. but i will try loosening the track bar bushings and start tightening them on the right side first. that's where the bronco got hit badly, see above. might be that the axle is warped there. maybe i can even it out a little more.

I think you mean "radius arm bushings" instead. The trackbar is the Panhard bar locating the frame and axle side-to-side.

The long control arms are the radius arms.

Adjusting those slightly (if even possible at this stage) effects caster, and due to their torsion bar effect, the suspension height by forcing the frame up or down on that side. If your truck sits level at this point, I would not mess with the C-bushing caps except to install the new C-bushings and make sure that the new ones go in evenly. So you don't impart any new lean!

What's in there now? Old rubber bushings with zero offset? Or polyurethane bushings with some offset?

still on the list:

- fix the winch control, probably buy a new winch cable

New wire rope will really dress things up, but how bad is your old cable? If you do buy new, the modern synthetic ropes will save you a substantial amount of weight. Both at the front of your Bronco, and the back of your wallet!

Depending on how long your existing one is, the weight savings could be huge.

Paul

- Joined

- Mar 8, 2007

- Messages

- 81,747

still on the list:

- fix the winch control, probably buy a new winch cable

- fix the fuel sending units and wiring

- bleed the brakes (again)

!

think about winch rope as well.. Over the cable

let me just focus on this one for now - sure, i meant the radius arm bushings. still too unfamiliar with that type of suspension set up

i have a new set of 4° poly on there for now, and that was just an educated guess with no suspension lift from reading on here.

but we were struggling to get the axle held in place - would there be anything we could possibly have screwed up? the bushings are in there with the correct orientation, we triple checked that.

i have a new set of 4° poly on there for now, and that was just an educated guess with no suspension lift from reading on here.

but we were struggling to get the axle held in place - would there be anything we could possibly have screwed up? the bushings are in there with the correct orientation, we triple checked that.

I think you mean "radius arm bushings" instead. The trackbar is the Panhard bar locating the frame and axle side-to-side.

The long control arms are the radius arms.

Adjusting those slightly (if even possible at this stage) effects caster, and due to their torsion bar effect, the suspension height by forcing the frame up or down on that side. If your truck sits level at this point, I would not mess with the C-bushing caps except to install the new C-bushings and make sure that the new ones go in evenly. So you don't impart any new lean!

What's in there now? Old rubber bushings with zero offset? Or polyurethane bushings with some offset?

- Joined

- Nov 3, 2003

- Messages

- 47,489

I don't think you would necessarily have messed something up. But it's possible that during installation of the 4 degree bushings one or more of them got distorted slightly from being pushed over the axle pads. That could possibly give you an additional half-degree or so I assume. Or they could have been molded slightly different at the factory

Never checked that possibility, but it sounds plausible at least.

If you install the 7 degree bushings, not only will you gain an additional 3 degrees of caster, but if you measure again afterwards and you have more or less variation than you have now, you will know that there is either some sort of deformation going on, OR the bushings themselves are just not consistent.

But money is still on the axle housing itself being inconsistently welded.

Paul

Never checked that possibility, but it sounds plausible at least.

If you install the 7 degree bushings, not only will you gain an additional 3 degrees of caster, but if you measure again afterwards and you have more or less variation than you have now, you will know that there is either some sort of deformation going on, OR the bushings themselves are just not consistent.

But money is still on the axle housing itself being inconsistently welded.

Paul

on a lighter note, my new aluminum radiator arrived today.

it's a champion cooling unit, 3row. looks decently welded.

made in china, shipped by a hongkong retailer from a warehouse somewhere in california.

bought through the international shipping program on ebay. shipping and taxes prepaid.

all for $180 right to my door... kind of insane.

it's a champion cooling unit, 3row. looks decently welded.

made in china, shipped by a hongkong retailer from a warehouse somewhere in california.

bought through the international shipping program on ebay. shipping and taxes prepaid.

all for $180 right to my door... kind of insane.

new radiator is in. engine runs, had to adjust the valves as it was ticking profusely.

the gauges have issues, though. voltage regulator already is a solid state unit, voltage is stable. both temp and fuel gauge go up when fully grounded. but they do not operate properly.

temp gauge goes up, but not fully up to operating temp. goes back down if i knock on the cluster?!?

fuel gauge shows no reading on either tank. i have a roughly correct ohm reading (48 ohms for a half full tank) on the rear sending unit and the same reading at the wire going to the gauge.

i suspect both gauges, as the newly bought oil gauge shows perfect readings.

so i ordered both.

i also ordered a new sending unit for the aux tank, as that sending unit shows a crazy ohm reading (120ohms for a half full tank). i suspect this to be faulty as well.

but all in all, i will soon have the bronco back on the road, with at least every technical aspect functioning properly. winch cables is still a bigger project. brake pedal is still spongy.

this is the offroad park i plan to visit first (site in german, but at least you can switch the language to dutch ):

):

https://www.furstenforest.eu/de/4x4-fahren/

the gauges have issues, though. voltage regulator already is a solid state unit, voltage is stable. both temp and fuel gauge go up when fully grounded. but they do not operate properly.

temp gauge goes up, but not fully up to operating temp. goes back down if i knock on the cluster?!?

fuel gauge shows no reading on either tank. i have a roughly correct ohm reading (48 ohms for a half full tank) on the rear sending unit and the same reading at the wire going to the gauge.

i suspect both gauges, as the newly bought oil gauge shows perfect readings.

so i ordered both.

i also ordered a new sending unit for the aux tank, as that sending unit shows a crazy ohm reading (120ohms for a half full tank). i suspect this to be faulty as well.

but all in all, i will soon have the bronco back on the road, with at least every technical aspect functioning properly. winch cables is still a bigger project. brake pedal is still spongy.

this is the offroad park i plan to visit first (site in german, but at least you can switch the language to dutch

https://www.furstenforest.eu/de/4x4-fahren/

74BroncoCO

Bronco Guru

- Joined

- Nov 3, 2004

- Messages

- 2,374

I had no idea there was anything like an offroad park in Germany. I did some research a few times and contacted a shop owner in Manheim, but I never got out to see him. I am sure I was not searching the correct terms.

It seems to be more accepted in France base on the types of vehicles I saw while on our trips.

But I am excited for you to take it out and see how well it does!

It seems to be more accepted in France base on the types of vehicles I saw while on our trips.

But I am excited for you to take it out and see how well it does!

Similar threads

City: Sacremento

Price: $34K

- Replies

- 6

- Views

- 596

City: Colorado Springs

Price: $14500

- Replies

- 29

- Views

- 2K